Dr. Arpita Chatterjee

HOD, Mechanical Engineering

The Department of Mechanical Engineering was established in the year 2009 at the very inception of Dr. Sudhir Chandra Sur Institute of Technology and Sports Complex. The department started with a 4 years B.Tech course (Capacity 30 Students) and later on, Master of Technology (Capacity 18 Students) came into being in 2012.

Mechanical engineering is one of the most sought-after core streams of engineering disciplines with multidisciplinary fields of work. The department is flourished with excellent laboratory facilities with a wide range of learning facilities, high quality teaching and laboratory staff. The Department stress upon all round development of the students by personal interaction between the staff and students beyond stipulated working hours and available for guidance even after they have passed out of the college. The Department aims at producing employable engineers who are capable of contributing meaningfully to the society.

Vision

To become a top teaching-cum-research Department in Mechanical Engineering in the country through an exemplary system that leads to entrepreneurship, innovation, values and quality

Mission

- DM1: To impart total quality education through effective hi-tech teach- ing-learning techniques and department-industries collaboration.

- DM2: To mold the young dynamic potential minds to emerge as full-fledged future professionals so as to achieve top ten ranking status in the national level.

- DM3: To achieve international standards to fulfill the Government's "Make In India" industrial policy through innovation and research

Programme Outcomes (PO):

Upon successful completion of 4-year B.E. degree programme, the ME students will be able to:

- PO1: Apply knowledge of mathematics, science, engineering fundamentals and an instrumentation engineering specialization to arrive solution for complex engineering problems.

- PO2: Identify, formulate and analyze complex engineering problems using first principles of mathematics, management and engineering.

- PO3: Design solutions for instrumentation engineering problems and develop Instrumentation and related system components or processes that meet specified needs with appropriate consideration for public health, safety, cultural, societal and environmental issues.

- PO4: Conduct investigations of complex problems using research-based knowledge and research methods including design of experiments, analysis and interpretation of data and synthesis of information to provide valid conclusions.

- PO5: Create, select and apply appropriate state-of-the-art techniques, resources and modern engineering and computing tools with an understanding of the limitations.

- PO6: Apply reasoning informed by contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to professional engineering practice.

- PO7: Understand the impact of professional engineering solutions in societal and environmental contexts and demonstrate knowledge of and need for sustainable development.

- PO8: Apply ethical principles and commit to professional ethics and responsibilities and norms of engineering practice.

- PO9: Function effectively as an individual, and as a member or leader in multidisciplinary teams.

- PO10: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as being able to comprehend and write effective reports and design documentation, make effective presentations and give and receive clear instructions.

- PO11:Recognize the need for and have the preparation and ability to engage in independent and life- long learning in the broadest context of technological change.

- PO12: Demonstrate knowledge and understanding of engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

Program Educational Objective (PEO)

The main objectives of the ME Department are:

- PEO1: To enhance the knowledge of the under graduates with fundamental Science of Engineering & Technical abilities.

- PEO2: To develop high level of technical competency combined with research and problem-solving skills to generate innovative solutions in Mechanical Engineering and/or related interdisciplinary areas.

- PEO3: To expand capability of methodological approach for taking decision and designing.

Program Specific Out Comes (PSO):

B. Tech in Electronics & Instrumentation Engineering

- PSO1: Graduates will be able to apply necessary mathematical and advanced software tools for design, analysis and fabrication of components used in the field of mechanical engineering.

- PSO2: Students will be able to gain knowledge about engines, machineries and develop critical skills to analyze the cause and effect of complicated mechanical pro-cesses.

- PSO3: Graduates will be able to gain team spirit for working in industrial projects as well as pursuing higher studies to contribute in mechanical engineering research and development.

Program

| Course Name | Degree | Intake Strength |

|---|---|---|

| B.Tech in Mechanical Engineering | B.Tech | 30 |

| M.Tech in Mechanical Engineering | M.Tech | 18 |

BOS

R & D

Faculty Publication

| YEAR | SCI/SCOPUS/REFFERED |

| 2024-2025 | 8 |

| 2023-2024 | 2 |

| 2022-2023 | 12 |

| 2021-2022 | 10 |

| 2020-2021 | 9 |

| 2019-2020 | 7 |

| 2018-2019 | 7 |

Student Publication

| YEAR | SCI/SCOPUS/REFFERED |

| 2024-2025 | 7 |

| 2023-2024 | 3 |

| 2022-2023 | 9 |

| 2021-2022 | 8 |

| 2020-2021 | 6 |

| 2019-2020 | 3 |

| 2018-2019 | 3 |

Events

| Department | Event Date/ Duration | Event Name | Resource Person Details | No. of Participants |

| ME | 26/09/2024 | Seminar on "Exploring Global Opportunities in Engineering Sciences: Integrating AI Applications, TOEFL Preparation, and Podcast Series" | Dr. Manojit Ghosh Metallurgical Department , IIEST Talk Prof. Snehanshu Pal , Department of Metallurgy and Materials Engineering, IIEST, Shibpur Mr. Saikat Dutta Senior Manager, East India & Bhutan, TOEFL & GRE Mr. Samir Nandi Director, Nest Innovations |

120 |

| ME | 08/11/2024 | "Academia & Industrial Summit 2024" | Dr. Monojit Dutta, Chief of Research Group for Product Development at TATA Steel Prof. P.P. Chattopadhyay, Director of NIAMT and former Dean of IIEST, Shibpur Prof. Manojit Ghosh, IIEST-Shibpur, Visiting Prof. at University of Michigan, PhD from Delft University of Technology, Netherlands, Associate Prof. Dr. Snehanshu Pal, IIEST-Shibpur, Postdoctoral Fellow at Pennsylvania State University, USA | 300 |

| ME | 14/02/2025 | Industrial Visit at Texmaco Rail & Engineering Ltd | 18 | |

| ME | 19/03/2025 | Industrial Visit at Binay Udyog Pvt. Ltd | 20 | |

| ME | 03/04/2025 | Project competition “Upcycling Brilliance” | Dr. Siddharth Bhattacharjee Mr. Sabyasachi Mitra Dr. Sayantan Chakraborty (HoD, EE) |

89 |

| ME | 07/04/2025 to 11/04/2025 | FDP on “Bridging Research & Funding—Unlocking Grants for Industry & Academia” | Dr. K. L. Sahoo, Chief Scientist, CSIR-NML, Jamshedpur Prof. Dr. Pankaj Kumar Roy, Former Director, School of Water Resources Engineering, Jadavpur University Prof. Dr. Koushik Biswas, Professor, IIT Kharagpur Dr. Surojit Gupta, Professor, University of North Dakota Dr. Nilrudra Mandal, Senior Principal Scientist, CSIR-CMERI, Durgapur |

100 |

Infrastructure

The department of Mechanical Engineering consists of the following laboratories with the most updated technologies & as per the educational standards:

| Sl No | Laboratory Name | Name of the Equipment |

| 1 | Applied Mechanics Lab |

|

| 2 | Material Testing Lab |

|

| 3 | Fluid Mechanics & Hydraulic M/c Lab |

|

| 4 | Metrology & Measurement Lab |

|

| 5 | Applied Thermodynamics & Heat Transfer Lab |

|

| 6 | Dynamic of Machine Lab |

|

| 7 | Air Conditioning & Refrigeration Lab |

|

| 8 | Machining & Machine Tools Lab |

|

| 9 | Manufacturing Technology Lab |

|

| 10 | Workshop |

|

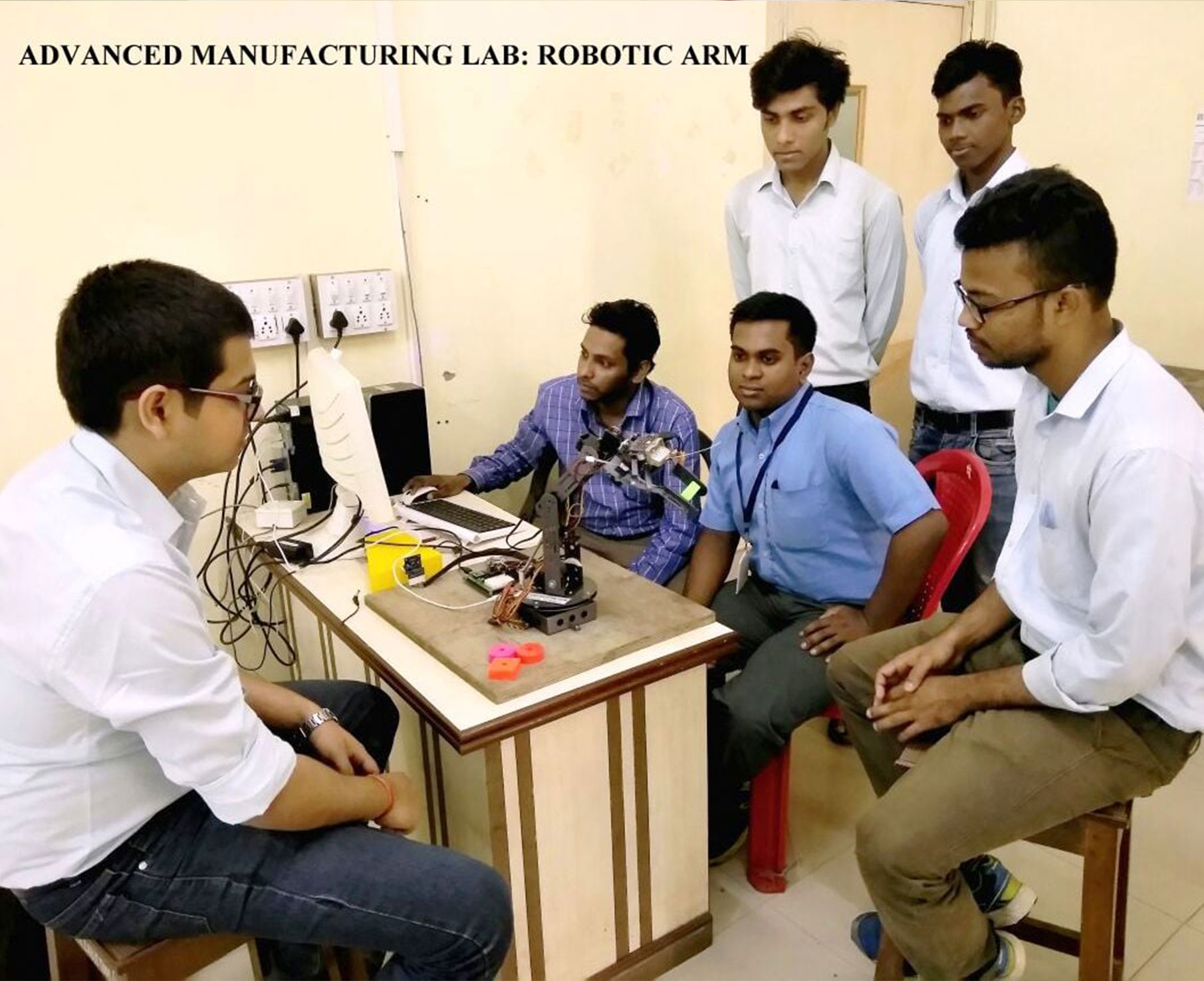

| 11 | Advance Manufacturing Technology Lab |

|

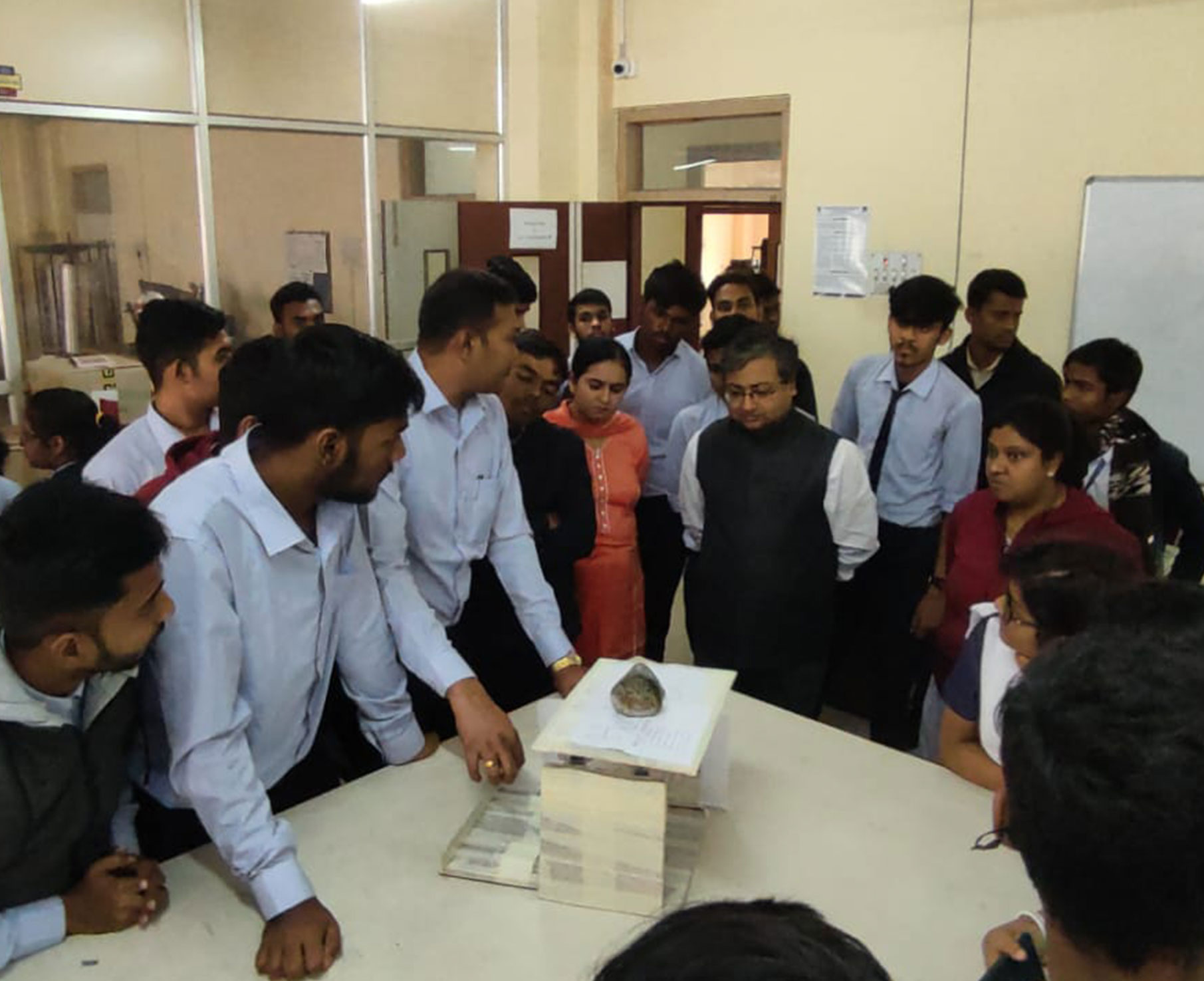

Photo Gallery